- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

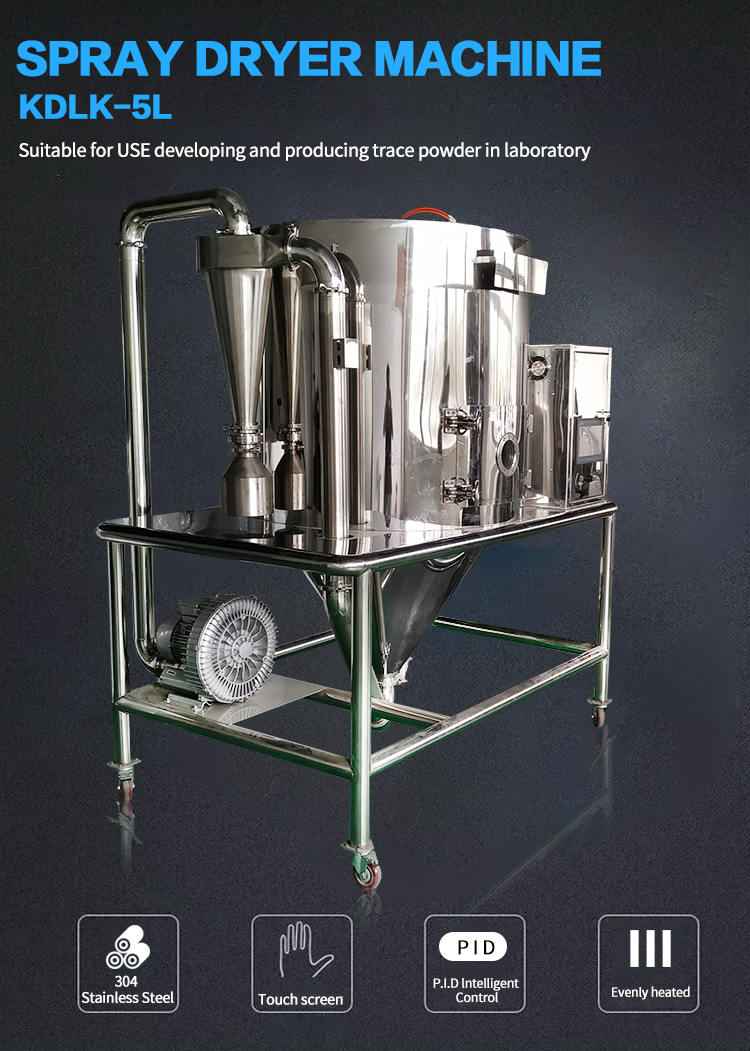

Advantage:

The spray drying chamber and collection device are made of transparent high temperature resistant high borosilicate glass, so that the spray drying process can be carried out in a pollution-free and stable environment. The spray drying experiment process of the entire laboratory spray dryer is visible, which is convenient to control the experiment process and can find and adjust problems in time. All glass elements are easy to disassemble and clean.

Features:

1.Equipped with quick-opening valves, materials can be collected uninterruptedly in continuous experiments.

2.Equipped with cooling water pipes, circulating water cooling the centrifugal pump motor, it is necessary to ensure that there is cooling water circulating during work.

3.Equipped with air inlet filter to ensure sample purity.

4.The material completes the drying process in a short time, which is suitable for the drying of heat-sensitive materials and can maintain the original characteristics of the materials.

5.The spray drying process is carried out in a pollution-free and stable environment.

6.The noise is very low, less than 60db, which meets the laboratory noise standard.

Included accessories:

High-quality high-borosilicate heat-resistant glass breaking drying chamber, high-quality high-borosilicate heat-resistant glass cyclone separator, high-quality high-bay silicon heat-resistant glass sample collection bottle, high-quality high-borosilicate heat-resistant glass rot sample collection tube, feeding silicone tube, Clamps and so on.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of certain accessories

FAQ:

1. What is the composition of the spray dryer?

The spray dryer includes: fan, air filter, electric heater, hot air distributor, atomizer, drying chamber, cyclone separator and feed pump; fan, air filter, electric heater, hot air distributor, mist The carburetor, the drying chamber and the cyclone separator are connected in turn through the ventilation pipe; the hot air distributor is set on the top of the drying chamber; the cyclone separator is used to remove the exhaust gas from the exhaust pipe and collect materials; the feed pump transports the liquid to the atomizer ; It also includes a control system for controlling the normal operation of the spray dryer.

2. What are the characteristics of spray dryers?

It is easy to realize dust-free and aseptic operation; improve the preservation of aromatic components; and can dry heat-sensitive materials.

3. What is the working principle of spray drying?

After filtering and heating, the air enters the air distributor on the top of the dryer, and the hot air enters the drying chamber evenly in a spiral shape. The material liquid passes through the high-speed centrifugal atomizer at the top of the tower body and sprays into extremely fine misty liquid beads, which are in contact with hot air and can be dried into finished products in a very short time. The finished product is continuously output from the bottom of the drying tower and the cyclone separator, and the waste gas is evacuated by the induced draft fan.

Material: Solution (include some suspension liquids) |

Max. water evaporation capacity of host machine: About 6L/h |

Inlet air temperature: From room temperature to 330℃ |

Outlet air temperature: From room temperature to 140℃ |

Heating method: Electrical heating |

Drying method: Centrifugal atomization |

Equipment material: 304 stainless steel |

Installation site: Indoor Working voltage: 380V 50-60HZ |

Floor area (length, width and height): 2.0m*1.3m*2.15m |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2020. ZZKD machinery equipment co., LTD All rights