- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

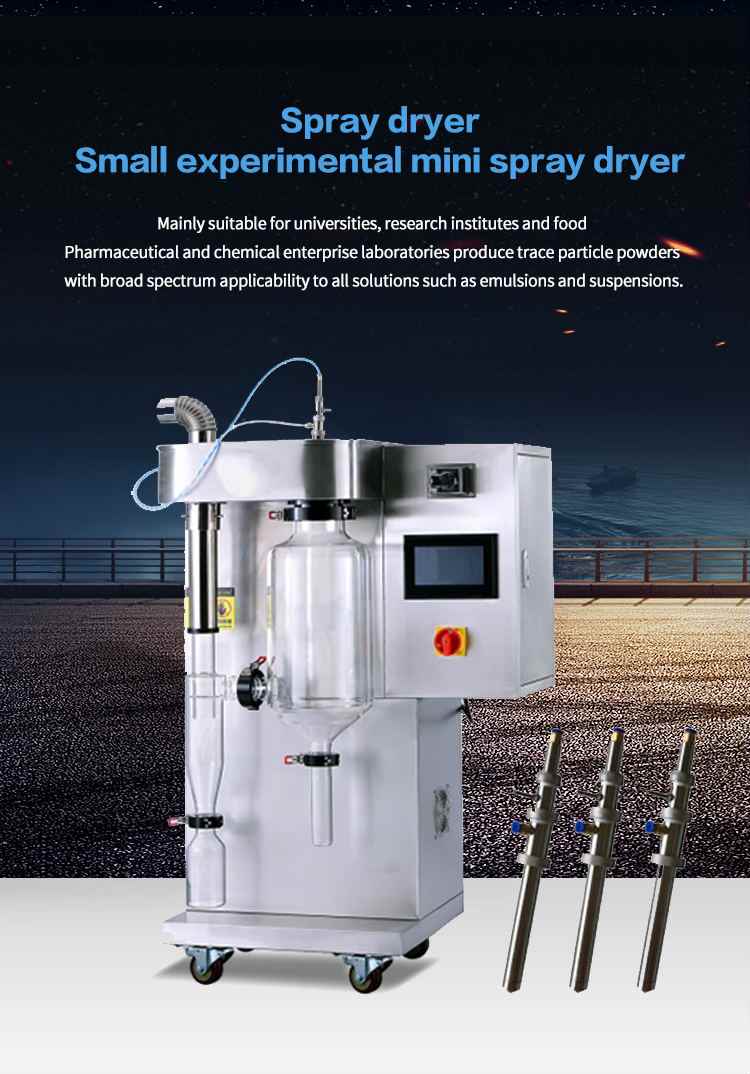

Advantage:

Laboratory spray dryer technology can dry solutions, suspensions, emulsions, etc. The resulting product has small particle size, uniformity, good fluidity and instant dissolution, and has been widely used in many fields such as food, pharmaceuticals, chemicals, and environmental protection.

Features:

1.Adopt a closed spray environment to prevent materials from being contaminated by bacteria.

2.The nozzle diameter is 0.5mm/0.7mm/0.75mm/1.0mm/1.5mm/2.0mm, etc. optional, and can be customized according to requirements.

3.Inlet air temperature control: 30℃~300~℃. Outlet temperature control: 30℃~200℃.

4.The product has good dispersibility, fluidity and solubility. Because the drying is completed in an instant, the product can maintain a uniform and fine granular shape.

5.The production process is simplified and the operation and control are convenient.

Included accessories:

High-quality high-borosilicate heat-resistant glass breaking drying chamber, high-quality high-borosilicate heat-resistant glass cyclone separator, high-quality high-bay silicon heat-resistant glass sample collection bottle, high-quality high-borosilicate heat-resistant glass rot sample collection tube, feeding silicone tube, Clamps and so on.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of certain accessories

FAQ:

1. How to clean the accessories of the high-speed centrifugal spray dryer?

Main unit: Open the door, remove all connecting pipes, clean up the tower wall inside the main unit, and sticky waste on the pipes.

Nozzle: Before you finish the experiment and finish feeding, you need to clean the internal pipeline with clean water (solvent that can dissolve the material). Finally, remove the pump head to clean the nozzle, shell and other sticky parts.

Fan: Check if there is any waste accumulated in the air inlet filter. If there is, clean it up.

2. What nozzles are generally used for high-speed centrifugal spray dryers

It adopts stainless steel nozzle, high efficiency and good atomization effect.

3. What is the collection system of the high-speed centrifugal spray dryer?

The collector is a classic powder collector, widely used by spray dryer systems. Its structure and shape directly affect the collection rate of powder, and it plays an important role in the spray dryer. For the spray dryer system, the performance of the collector is often considered through observations of actual operations and experimental results.

Model | SD-5 | SD-10 | SD-25 | SD-50 | SD-100 | SD-150 | SD-200~2000 |

Inlet temperature (°C) | 140-350 | ||||||

Outlet temperature (°C) | 80-90 | ||||||

Moisture maximum evaporation (kg/h) | 5 | 10 | 25 | 50 | 100 | 150 | 200-2000 |

Rotation form of centrifugal spray head | Compressed air transmission | Mechanical transmission | |||||

Rotating speed (r.p.m) | 25000 | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

Diameter of spray disc (mm) | 50 | 50 | 100 | 120 | 140 | 150 | 180-340 |

Heat source | Electricity | Electricity | Electricity + steam | Electricity+ steam, fuel oil, gas | According to the actual situation | ||

Electric heating power (kw) | 9 | 20 | 36 | 63 | 81 | 99 | |

Length×width×height (m) | 1.8×0.93× 2.2 | 3.2x1.5x 2.4 | 3×2.7× 4.26 | 3.7×3.2× 5.1 | 4.6×4.2× 6 | 5.5×4.5×7 | |

Dry powder recovery rate(%) | ≥95 | ||||||

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2020. ZZKD machinery equipment co., LTD All rights