- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

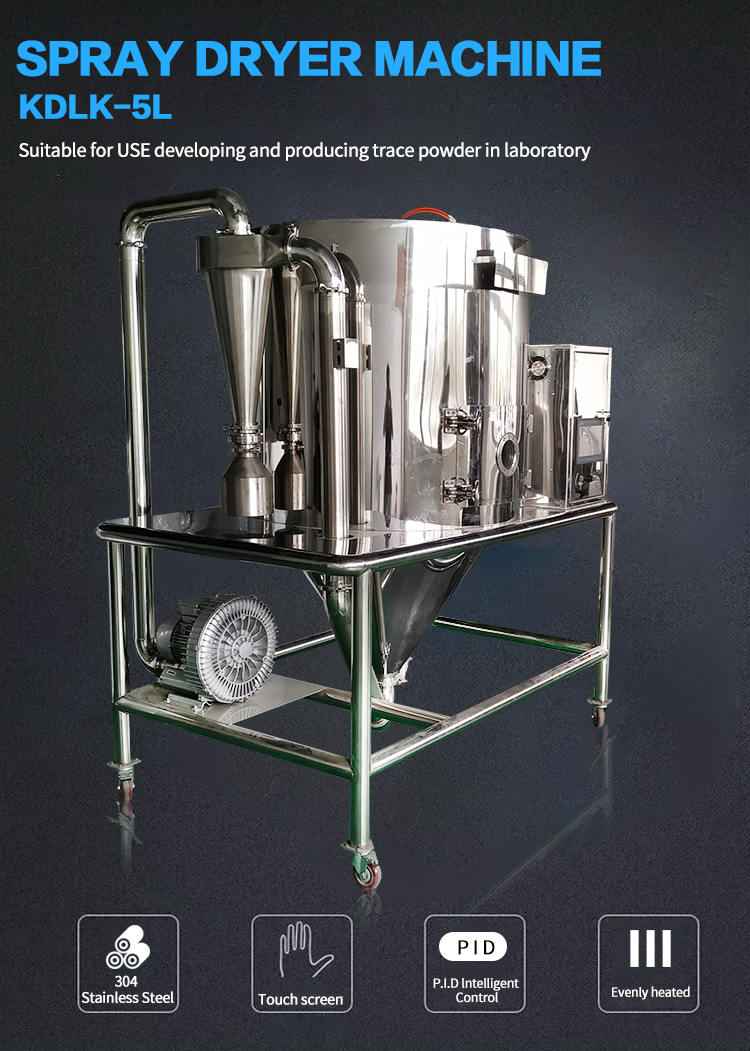

Advantage:

The spray drying equipment we produce has low noise and fast drying speed during the drying process. The operation is simple and convenient. Suitable for drying heat sensitive materials. It has good dispersibility, fluidity and solubility.

Features:

1.Use the touch screen to display operation, control temperature, air flow, air pressure, pump speed and deblocking frequency, etc.

2.Full borosilicate glass, easy to visually monitor the process status.

3.The drying speed is fast, and the surface area of the material liquid is greatly increased after atomization. In the hot air flow, 95%-98% of the water can be evaporated instantly, and the drying time is only a few seconds.

4.It has good uniformity, fluidity and solubility, and the product has high purity and good quality.

5.The production process is simplified and the operation and control are convenient. For liquids with a moisture content of 40-60% (up to 90% for special materials), it can be dried into powder products at one time.

Included accessories:

High-quality high-borosilicate heat-resistant glass breaking drying chamber, high-quality high-borosilicate heat-resistant glass cyclone separator, high-quality high-bay silicon heat-resistant glass sample collection bottle, high-quality high-borosilicate heat-resistant glass rot sample collection tube, feeding silicone tube, Clamps and so on.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of certain accessories

FAQ:

1.What is the collection system of High and low temperature spray dryer?

The collector is a classic powder collector, widely used by spray dryer systems. Its structure and shape directly affect the collection rate of powder, and it plays an important role in the spray dryer. For the spray dryer system, the performance of the collector is often considered through observations of actual operations and experimental results.

2.What is the working principle of the high and low temperature spray dryer?

After filtering and heating, the air enters the air distributor on the top of the dryer, and the hot air enters the drying chamber evenly in a spiral shape. The material liquid passes through the high-speed centrifugal atomizer at the top of the tower body and sprays into extremely fine misty liquid beads, which are in contact with hot air and can be dried into finished products in a very short time. The finished product is continuously output from the bottom of the drying tower and the cyclone separator, and the waste gas is evacuated by the induced draft fan.

3.What are the application fields of high and low temperature spray dryer?

Chemicals, plastic resins, food industry, sugar, ceramics, pharmaceuticals, etc.

Material: Solution (include some suspension liquids) |

Max. water evaporation capacity of host machine: About 6L/h |

Inlet air temperature: From room temperature to 330℃ |

Outlet air temperature: From room temperature to 140℃ |

Heating method: Electrical heating |

Drying method: Centrifugal atomization |

Equipment material: 304 stainless steel |

Installation site: Indoor Working voltage: 380V 50-60HZ |

Floor area (length, width and height): 2.0m*1.3m*2.15m |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2020. ZZKD machinery equipment co., LTD All rights