- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

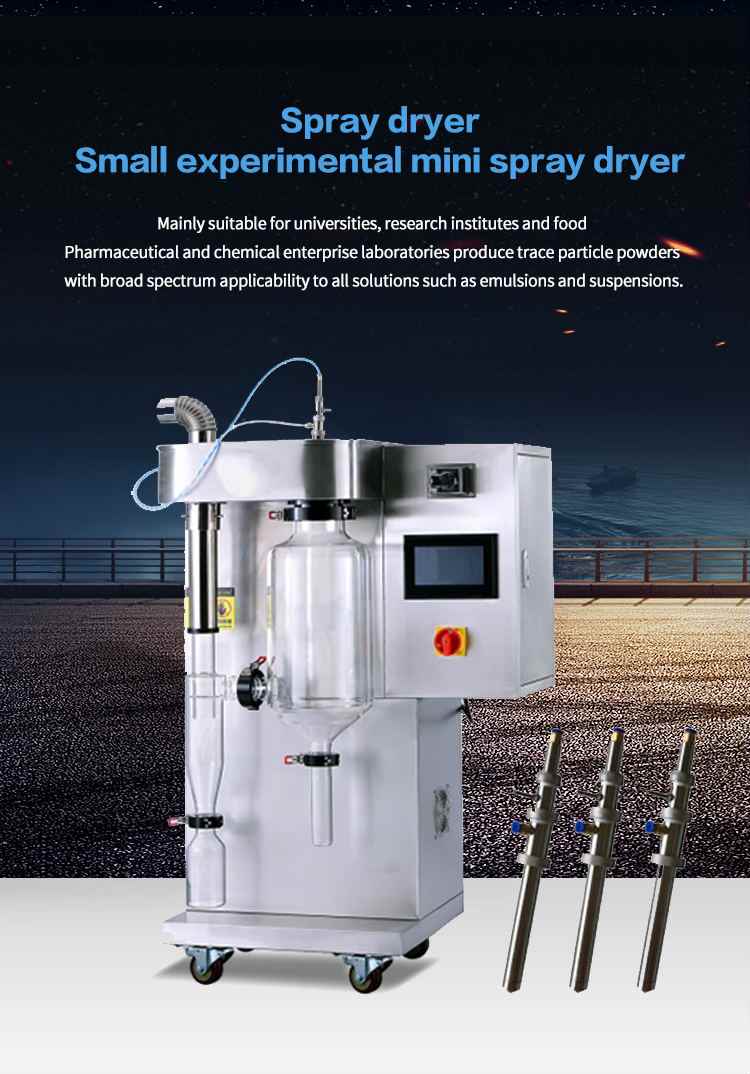

The small scale spray dryer (mini spray dryer) produced by ZZKD is mainly used in universities, research institutes, and food, biology, beverage, chemical, material, pharmaceutical and other enterprises for laboratory research and development and production of granular powder. It is suitable for all solutions such as emulsions. ﹑The suspension has a wide range of applicability and is suitable for drying heat-sensitive materials. Such as biological products, biological pesticides, enzyme preparations, etc., and can keep the active ingredients of these materials undamaged after drying.

1.The spray dryer has dual control modes of automatic control and manual control.

2.The spray dryer adopts stainless steel nozzle, which has high efficiency and good atomization effect.

3.The atomization system adopts the atomization structure of two-fluid spray, and the whole machine is made of high-quality 304 stainless steel.

4.The average drying time is 0.8-1.5 seconds, and the drying speed is very fast.

5.The system adopts PID temperature control technology with real-time adjustment to make the temperature control of the whole temperature zone accurate.

6.High-efficiency volute cyclone separator for material recovery.

●Special protection function, the fan will not start and the heater will not start.

●Built-in imported oil-free air compressor with noise less than 50db.

●Equipped with air inlet filter to ensure sample purity.

●The dried product has a uniform particle size, more than 95%of the dry powder is at the same particle size.

1. Nlet air temperature control: 30~300 °℃

2. Outlet temperature control: 30~150 °℃

3. Evaporated water volume: 1500mL/H~2000ml /h4. Maximum feed volume: 2000mL /H

5. Minimum feed volume: 50mL

6. Feeding method: peristaltic pump adjustment7.Average drying time: 1.0~1.5S

8. Electric heater power: 4KW AC220V single-phase ground

9. Fan: 0.2KW maximum air volume 5.6m3/ min maximum air pressure 1020Pa10. Air compressor:0.2KW maximum gas output 4.2 m3/h

11. Working pressure of compressed air: 2~~3Bar

12. Equipment dimensions: 1300mm (height) x 650mm (length) x800mm (width)13. Nozzle diameter: 1.00mm

14. Equipment weight: 130KG

High-quality high-borosilicate heat-resistant glass breaking drying chamber, high-quality high-borosilicate heat-resistant glass cyclone separator, high-quality high-bay silicon heat-resistant glass sample collection bottle, high-quality high-borosilicate heat-resistant glass rot sample collection tube, feeding silicone tube, Clamps and so on.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of certain accessories

FAQ:

1. What is the hot air circulation system of The small scale spray dryer (mini spray dryer)?

In the process of spray drying, the hot air circulation system is the main power and carrier for drying, collection, and steam discharge. Adopt negative pressure suction method to make hot air circulate in the system. Its advantages are: the hot air is controlled in the system, no leakage, will not affect the experimental environment, so that the experimental staff can work in a clean experimental environment.

2. What is the working principle of The small scale spray dryer (mini spray dryer)?

After filtering and heating, the air enters the air distributor on the top of the dryer, and the hot air enters the drying chamber evenly in a spiral shape. The material liquid passes through the high-speed centrifugal atomizer at the top of the tower body and sprays into extremely fine misty liquid beads, which are in contact with hot air and can be dried into finished products in a very short time. The finished product is continuously output from the bottom of the drying tower and the cyclone separator, and the waste gas is evacuated by the induced draft fan.

3. What are the characteristics of The small scale spray dryer (mini spray dryer)?

It is easy to realize dust-free and aseptic operation; improve the preservation of aromatic components; and can dry heat-sensitive materials.

Inlet air temperature: | Room temperature to 300°C |

Outlet temperature: | Room temperature to 140℃ |

Water evaporation capacity : | 0-2000ml/h |

Stainless steel nozzle: | Nozzle diameter Φ0.75mm |

Display: | 7-inch LCD touch operation display |

Real-time temperature control: | Error ±1℃ |

Real-time display temp. accuracy: | 0.1℃ |

Fan: | 0.75kW (aluminum alloy supercharged) |

Maximum drying air volume: | 105m³/h |

Inverter power: | 0.75kW |

Air compressor: | 0.55kW (oil-free) |

Whole machine power: | 2.2kW/4.4kW/8.8kW 220V |

Dimensions: | 650×500×1500mm |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2020. ZZKD machinery equipment co., LTD All rights