How does spray dryer works

Our spray dryers include small spray dryers, laboratory spray dryers, large spray dryers, etc.

What is a spray dryer?

Spray drying equipment is one of the new modern drying technologies. At the beginning of the 20th century, this equipment was mainly used for the manufacture of skimmed milk powder and began to be industrially used in the food industry. With the continuous development and improvement of spray drying technology, this technology has been widely used in the world, for example, it is used in the production of milk powder, whey powder, cream powder, egg powder, juice powder, instant coffee, etc. in the food industry. It is also commonly used in other industries such as pharmaceuticals, biological products, detergents, ceramics, and environmental protection.

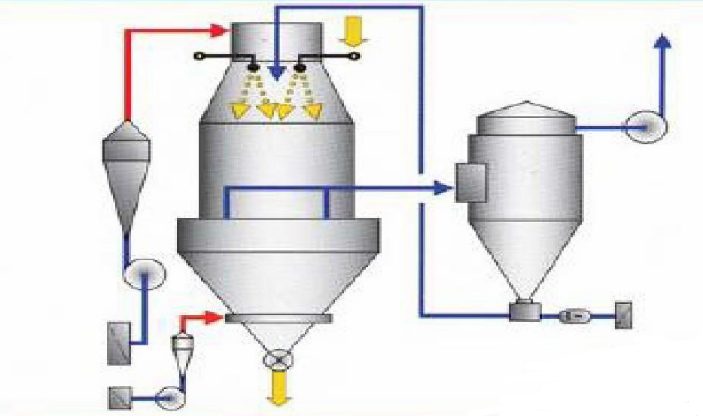

How does spray dryer works

The spray dryer is a vertical parallel-flow pressure drying equipment designed by our company. Its working principle is to disperse the material to be dried into very fine mist-like particles through mechanical action (to increase the evaporation area of water and accelerate the drying process), and after contact with hot air, most of the water is instantly removed Removal, so that the solid matter in the material is dried into powder.

The spray dryer has fast drying speed, high efficiency, few procedures, and saves manpower. Especially for heat-sensitive materials, the product quality is excellent, but when the operation is unskilled and the adjustment control lacks experience, it is easy to cause some problems. The following is a summary of possible problems in production and their causes and remedial measures.

There is noise or vibration when the centrifugal nozzle is running

Mainly due to improper cleaning and maintenance of the nozzle, the nozzle has residual substances or the spindle is bent and deformed, or the centrifugal disk is not well balanced.

Solution: Check if there are any remaining substances in the spray disk, if there is any, clean it in time; if the spindle is found to be abnormal, replace it; re-adjust or replace the dynamic balance of the centrifugal disk.

Centrifugal nozzle speed is too low

The main reason is that the parts of the centrifugal nozzle are out of order, so stop using the nozzle and check the internal parts of the nozzle.