Pilot scale spray dryer equipment for sale

Our spray drying equipment includes small-scale spray drying equipment, pilot-scale spray drying equipment, large-scale spray drying equipment, etc. We are a professional spray drying equipment supplier, and we have high-quality services and high-quality equipment.

Characteristics of pilot spray drying:

1. Fast drying speed. After the material liquid is sprayed, the surface area is greatly increased. In the high-temperature airflow, 95%-98% of the water can be evaporated instantly, and the drying time is only a few seconds.

2. The co-current spray drying form can make the liquid droplets flow in the same direction as the hot air. Although the temperature of the hot air is higher, because the hot air enters the drying room and immediately contacts the spray droplets, the indoor temperature drops sharply, and the wet bulb temperature of the material Basically unchanged, so it is also suitable for drying heat-sensitive materials.

3. Wide range of use. According to the characteristics of the material, it can be used for hot air drying, centrifugal granulation and cold air granulation. Most products with very different characteristics can be produced by this machine.

4. The entire operation is airtight, suitable for clean production areas. Because the spray drying operation is carried out in a closed tower, cross-contamination and dust flying are avoided, and it is suitable for the production of raw materials in the pharmaceutical industry, especially the production of sterile raw materials.

5. Since the drying process is completed in an instant, the particles of the finished product can basically maintain the approximate spherical shape of the droplets, and the product has good dispersibility, fluidity and solubility.

6. The production process is simplified, and the operation and control are convenient. Spray drying is usually used for solutions with a solid content of less than 60%. After drying, there is no need to pulverize and screen, which reduces the production process and simplifies the production process. For the product's particle size, bulk density, and moisture content, within a certain range, the operating conditions can be changed for adjustment, and the control and management are very convenient.

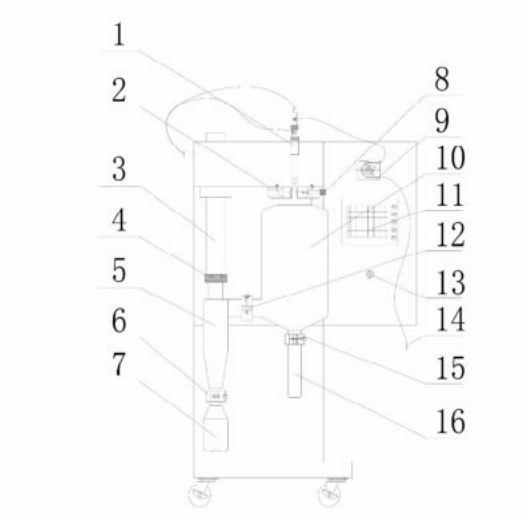

The structure of pilot spray drying:

1. Atomizer; 2. Large clamp; 3. Exhaust pipe; 4. Lock nut; 5. Cyclone; 6. No. 1 clamp; 7. Collection bottle; 8. Large clamp; 9. Peristalsis Pump; 10, drying room; 11, touch screen; 12, 2 clamps; 13, power switch; 14, feed pipe; 15, 3 clamps; 16, collection tube

Application range of pilot spray drying:

1. Chemical industry: battery raw materials, basic dyes and pigments, dye intermediates, compound fertilizers, formaldehyde silicic acid, catalysts, sulfuric acid agents, amino acids, white carbon black, etc.

2. Plastic resin: AB, ABS emulsion, urea-formaldehyde resin, phenolic resin, dense rubber (urea) formaldehyde resin, polyethylene, polyvinyl chloride, etc.

3. Food industry: fat-rich milk powder, intestines, cocoa milk powder, milk replacer powder, animal blood powder, egg white (yellow) whole egg powder, etc.

4. Food and plants: oats, chicken juice, coffee, instant tea, flavored meat, protein, soybean, peanut protein, hydrolysate, etc.

5. Sugars: corn syrup, corn starch, glucose, pectin, maltose, potassium sorbate, etc.

6. Ceramics: alumina, ceramic tile materials, magnesium oxide, talc, etc.